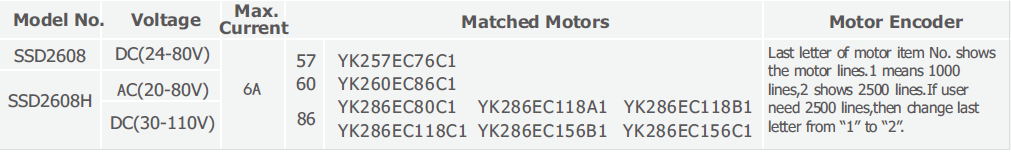

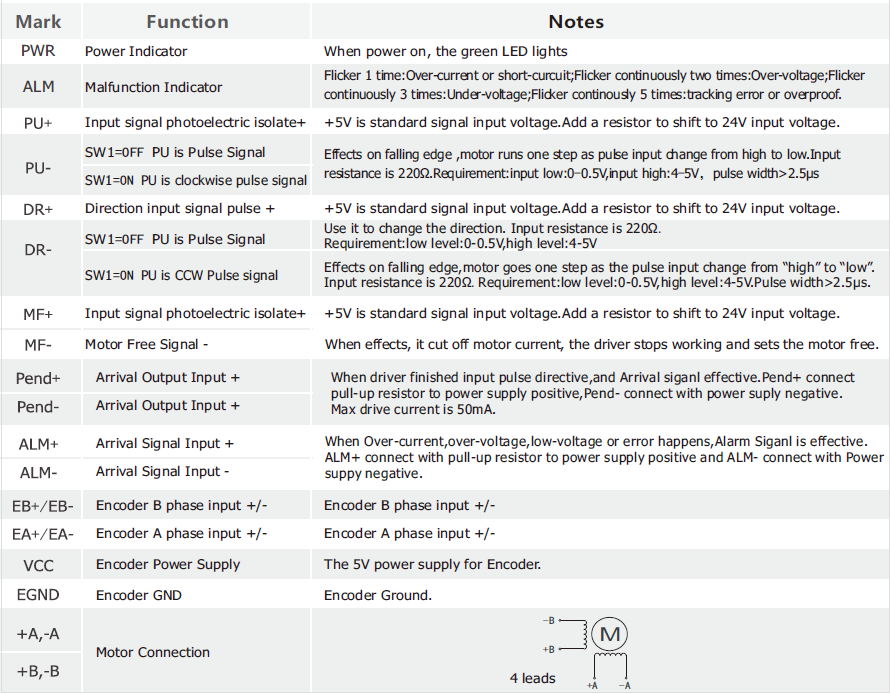

SSD2608H takes the advantages of 32-bit DSP control technology and power angle control technology, maximum speed reaches more than 3000rmp. It’s high-speed torque attenuation is much lower than ordinary open-loop stepper drive, which can greatly enhance the high-speed performance and torque efficiency, and reduce motor heating/vibration, thus to enhancing machine’s efficiency and accuracy.

The use of load-based current control technology can effectively reduce motor heat, extend motor life. The position and warning output signal will assist host computer to monitor and control. And the position warning function ensures safe operation of processing machine.